Στερεό άκρο

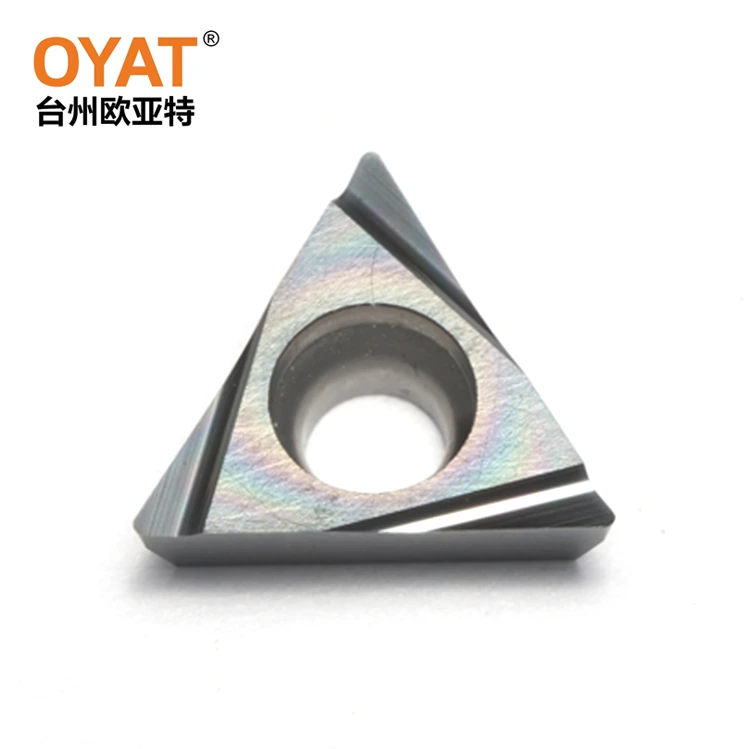

Στο πεδίο της κοπής μετάλλων, το εργαλείο άλεσης χάλυβα OYT βολφραμίου ξεχωρίζει για την ανώτερη απόδοση του, καθιστώντας το βασικό εργαλείο σε διάφορα σενάρια κατεργασίας ακριβείας. Αυτό το εργαλείο είναι κατασκευασμένο από χάλυβα βολφραμίου και συνδυάζει καρβίδιο βολφραμίου (WC) με κοβάλτιο (CO) ως συνδετικό υλικό μέσω της μεταλλουργίας της σκόνης. Το καρβίδιο βολφραμίου παρέχει μια εξαιρετικά υψηλή σκληρότητα πάνω από το HRA90, ενώ το κοβάλτιο εξασφαλίζει σκληρότητα. Μαζί, παρέχουν το εργαλείο άλεσης με εξαιρετική σκληρότητα, αντοχή στη φθορά και δυνατότητες κατά του chipping, καθιστώντας το κατάλληλο για περιβάλλοντα κοπής υψηλής αντοχής. Το υπόστρωμα χάλυβα βολφραμίου είναι πολύ πιο δύσκολο από τον χάλυβα υψηλής ταχύτητας, διατηρώντας μια αιχμηρή άκρη ακόμη και σε κοπή υλικού υψηλής αντοχής πάνω από 60HRC. Η επικάλυψη νανο-επιτόπια ενισχύει περαιτέρω την απόδοση του εργαλείου, με δοκιμές που δείχνουν ότι τα επικαλυμμένα εργαλεία άλεσης έχουν βελτίωση αντίστασης φθοράς άνω του 90% σε σύγκριση με τα μη επικαλυμμένα εργαλεία. Αυτό επιτρέπει τη σταθερή κοπή υλικών υψηλής σκληρότητας, όπως τα σβησίλα και τα κράματα τιτανίου, μειώνοντας τη συχνότητα των αλλαγών εργαλείων.35 ° Ο σχεδιασμός της σπειροειδούς γωνίας, σε συνδυασμό με αυλάκωση απομάκρυνσης τσιπ μεγάλης χωρητικότητας, εξασφαλίζει ομαλότερη εκκένωση τσιπ. Σε σύγκριση με τους παραδοσιακούς κοπτήρες άλεσης, η αποτελεσματικότητα της επεξεργασίας μπορεί να αυξηθεί κατά 50% υπό τις ίδιες συνθήκες εργασίας. Για παράδειγμα, στην άλεση των κοιλοτήτων κράματος αλουμινίου, ο μύλος στερεών άκρων OYT μπορεί να επιτύχει τροφοδοσία υψηλής ταχύτητας, μειώνοντας τον κύκλο επεξεργασίας και ευθυγραμμίζοντας με το ρυθμό της παραγωγής παρτίδας.

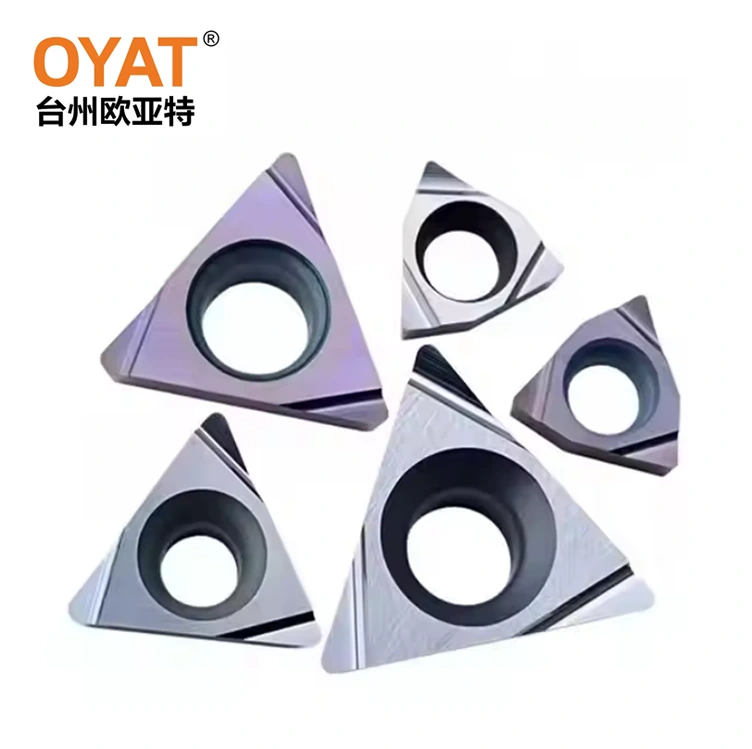

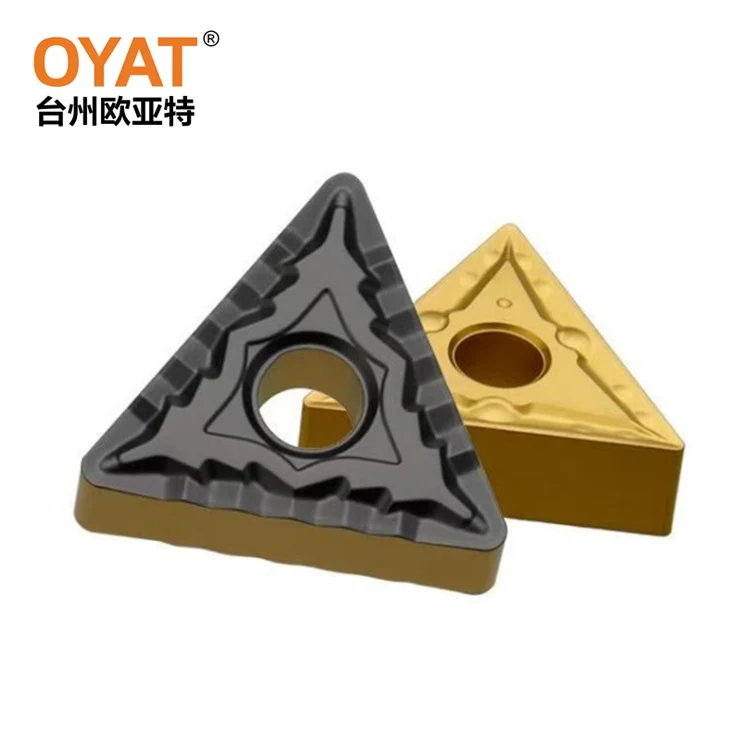

Το OYT Solid End Mill διαθέτει ενισχυμένο σχεδιασμό τριγωνικού άκρου, το οποίο ενισχύει σημαντικά την ισχύ της ακμής κατά τη μηχανική κατεργασία. Οι δοκιμές πίεσης έχουν δείξει ότι αυτός ο σχεδιασμός αυξάνει την αντίσταση του εργαλείου στο τσιπς κατά 80%. Σε σενάρια διαλείπουσα κοπής, όπως τα καλούπια, και κάτω από τις συνθήκες φορτίου κρούσης, η διάρκεια ζωής του εργαλείου επεκτείνεται κυρίως, μειώνοντας τον κίνδυνο θραύσης των εργαλείων. Η διαδικασία διαμόρφωσης του OYT Solid End Mill εξασφαλίζει υψηλή ακρίβεια εργαλείων, με την εκδρομή με άκρη να ελέγχεται μέσα σε 0,005mm. Κατά την κατεργασία των σύνθετων επιφανειών, όπως αυτές που βρίσκονται στα ένθετα του κινητήρα αεροσκαφών, μπορεί να αναπαράγει με ακρίβεια το περίγραμμα, να συναντάτε τις απαιτήσεις τραχύτητας της επιφάνειας RA0.8μm ή λιγότερο και να μειώσει τα επακόλουθα στάδια στίλβας κατά 30%.

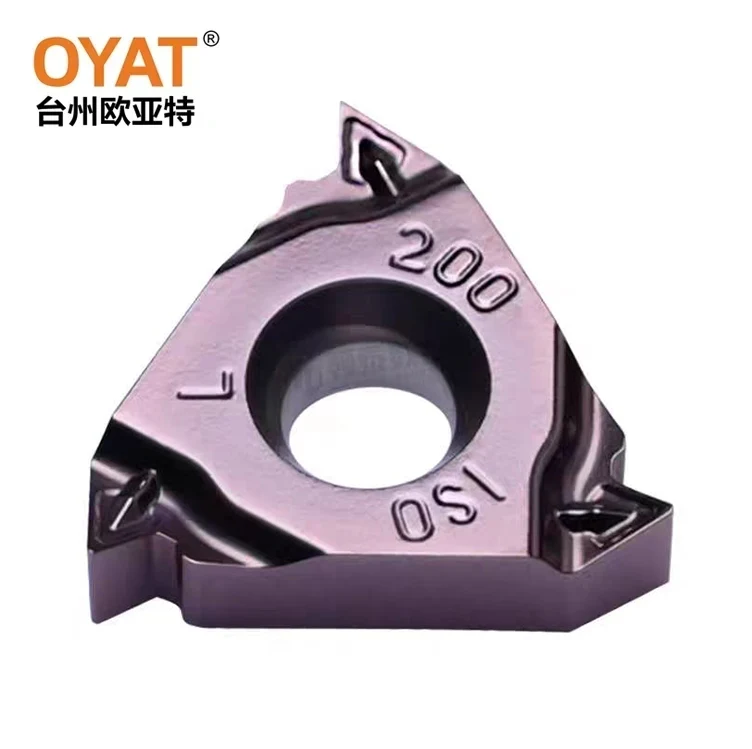

Σκηνοειδή μέρη: Κατάλληλα για το εύρος σκληρότητας των 58 έως 65hrc, όπως ο χάλυβας μούχλα CR12MOV και ο χάλυβας υψηλής ταχύτητας W6MO5CR4V2, αυτά τα μέρη μπορούν να ολοκληρώσουν αποτελεσματικά την κατεργασία των κοιλοτήτων και των διατρήσεων ακριβείας. Υλικά υψηλής στενότητας: Για τα συνήθως χρησιμοποιούμενα υλικά υψηλής σκληρότητας, η υψηλή θερμική σκληρότητα του Tungsten Steel επιτρέπει τη σταθερή κατεργασία σε θερμοκρασίες κοπής που υπερβαίνουν τα 600 ℃, καθιστώντας το ιδανικό για άλεση διαρθρωτικών εξαρτημάτων αεροπορίας. Ανοξείδωτος χάλυβα: Για ανοξείδωτους χάλυβες όπως 304 (20-25HRC) και 316L, αυτό το υλικό αντιμετωπίζει ζητήματα μείωσης της προσκόλλησης και της φθοράς των εργαλείων, καθιστώντας το κατάλληλο για την επεξεργασία ιατρικών συσκευών και τμημάτων μηχανημάτων τροφίμων.

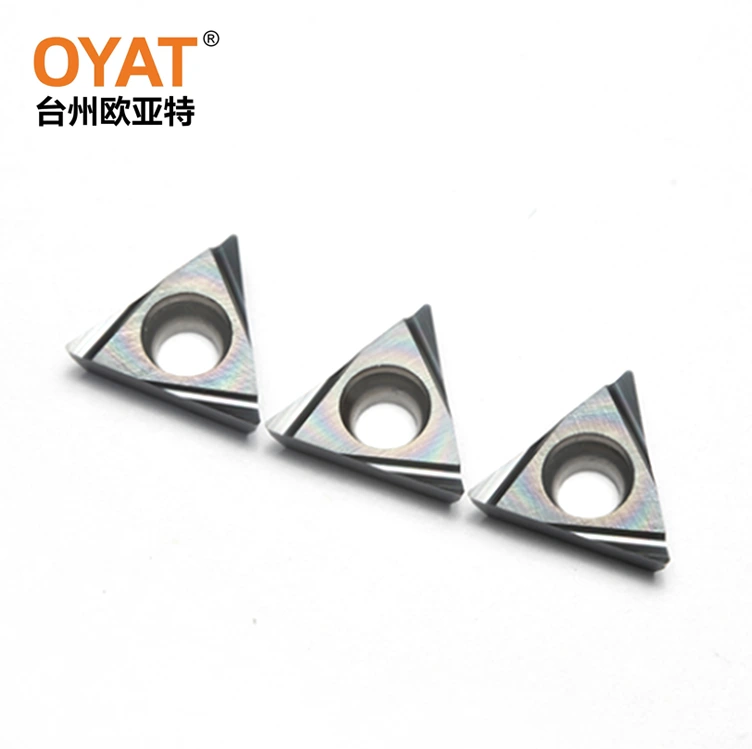

Σκληρότητα: Το υπόστρωμα χάλυβα βολφραμίου έχει σκληρότητα τουλάχιστον 90hra και η σκληρότητα της επιφάνειας μετά την επικάλυψη μπορεί να υπερβεί τα 3000HV. Γωνιά σπειροειδούς: Ο σχεδιασμός διαθέτει μια γωνία σπειροειδούς 35 ° για την εξισορρόπηση των δυνάμεων εκκένωσης και κοπής των τσιπ. Για συγκεκριμένες εφαρμογές, η γωνία μπορεί να ρυθμιστεί από 25 ° έως 45 °. Εισαγάγετε διάμετρο: Οι κοινές προδιαγραφές κυμαίνονται από φ1 έως φ20mm, με διαμέτρους λαβής συμβατές με CAT40, BT30 και άλλους κάτοχοι εργαλείων, εξασφαλίζοντας συμβατότητα με διάφορα μηχανήματα. Επεξεργασία Επεξεργασία Σκληρότητα: Η τυπική κάλυψη είναι έως και 65hrc και οι ειδικές προσαρμοσμένες επιλογές μπορούν να επεκταθούν σε 70hrc

Σε σύγκριση με τα ένθετα συγκόλλησης, ο μύλος Solid End OYT προσφέρει σημαντικά πλεονεκτήματα: δεν έχει ραφές συγκόλλησης, αποφεύγοντας αποτελεσματικά τη μείωση της αντοχής που προκαλείται από τη ζώνη που επηρεάζεται από τη θερμότητα. Είναι πιο αξιόπιστο κάτω από τα φορτία κρούσης και μειώνει τον κίνδυνο θραύσης εισάγει έως και 70% σε σκληρές επιχειρήσεις άλεσης. Η συνεπής ακρίβεια εξασφαλίζει την ακρίβεια της ακμής, με διαστασιολογικές ανοχές στην επεξεργασία των παρτίδων να είναι μικρότερη από 0,01mm, η οποία είναι ανώτερη από τις παραλλαγές που προκαλούνται από την αντικατάσταση των ένθετων σε συμβατικά ένθετα. Το OYT Integral Tungsten Carbide Cutter Carbide, κατασκευασμένο από καρβίδιο βολφραμίου, διαθέτει υψηλή σκληρότητα, αποτελεσματικότητα και ακρίβεια, καθιστώντας την βασική επιλογή για εταιρείες που δίνουν προτεραιότητα στην αποτελεσματική και ακριβή κατεργασία. Είναι βαθιά ενσωματωμένο σε βιομηχανίες όπως καλούπια, αεροπορία και αυτοκινητοβιομηχανία, πιέζοντας συνεχώς τα όρια της κοπής σε εφαρμογές υψηλής αντοχής, υψηλής ακρίβειας, παρέχοντας αξιόπιστες λύσεις εργαλείων για προχωρημένη κατασκευή.